Non-Ambient X-ray Diffraction

Non-ambient X-ray diffraction (NA-XRD) is an advanced technique used to study materials under non-ambient conditions, such as changes in temperature, pressure, humidity, and more. In contrast to traditional X-ray diffraction, which analyzes samples at ambient conditions, NA-XRD allows researchers to simulate real-world environments or extreme conditions to observe how materials behave under different external parameters.

This method is critical for understanding how structural changes, phase transitions, and reactions occur in various materials, ranging from metals and ceramics to pharmaceuticals and polymers. By applying these conditions in situ during X-ray diffraction experiments, NA-XRD helps bridge the gap between laboratory results and real-life applications, making it an invaluable tool in industries like metallurgy, pharmaceuticals, chemical processing, and more.

Fundamentals of NA-XRD

In NAXRD, the sample is influenced by external parameters during the experiments. Some of the most important parameters are listed below:

- Temperature

- Pressure

- Relative humidity

- Gas environment

These parameters result in a variety of material changes that can be investigated in situ. Some of them are listed below:

- Material formation / structure changes

- Chemical reactions and decomposition processes

- Heat treatment and annealing

- Calcination and sintering

- (De)Hydration processes

- Catalyst activation and deactivation

The investigation of these processes is not only interesting for the scientific community, but also for many technological processes used in industry.

Application examples will be given at the end of this article.

Principal Instrumental Design Aspects

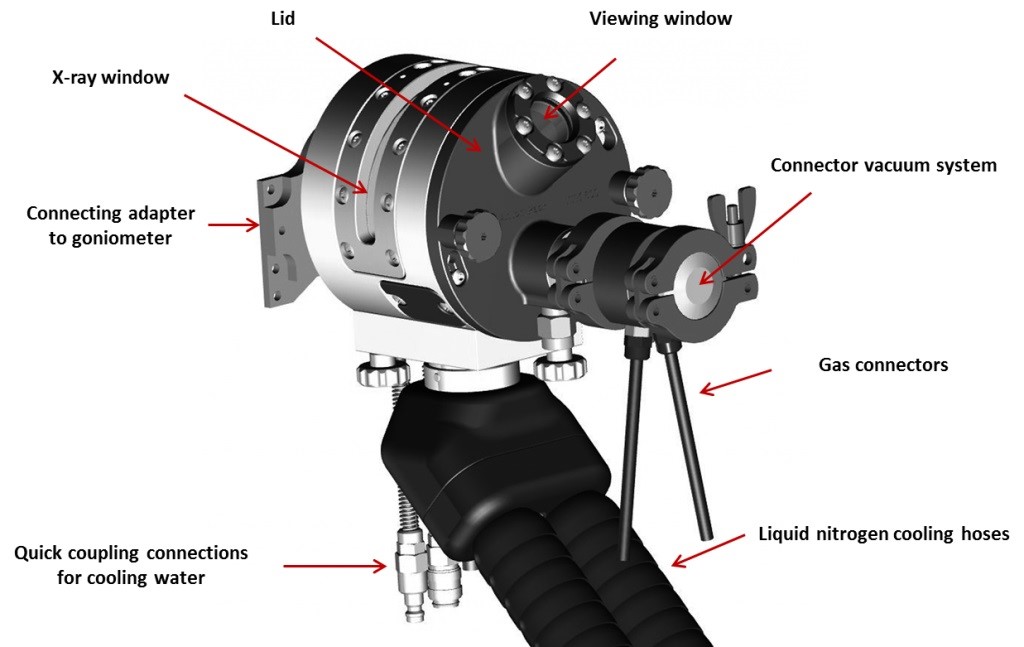

The principal components of a non-ambient heating attachment are shown in Figure 1. On the rear side of the attachment, a mechanical interface/adapter for a specific diffractometer is located. To keep the temperature load on the diffractometer at a minimum at all times, and protect the attachment from overheating, the housing is cooled with water. X-ray windows in the housing allow the X-ray beam to pass through the attachment. Window materials like Kapton, Graphite, PEEK or Beryllium can be used.

The round shape of the instrument ensures that the beam path through the window is constant at all angles. Different additional elements like a viewing window, connectors for a vacuum system, gas connectors, or cooling hoses for the introduction of liquid nitrogen can also be present.

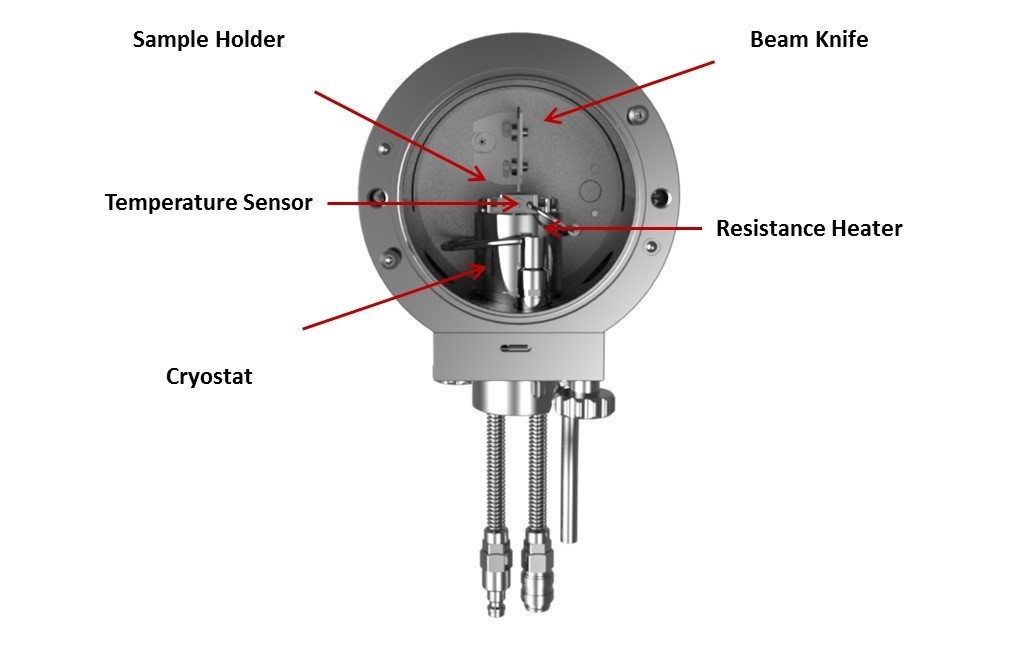

An exemplary picture of the internal design of a non-ambient attachment is shown in Figure 2. In the center of the attachment the sample holder is located. The temperature sensor is usually mounted close to, or inside, the sample holder. This ensures that the temperature measurement is repeatable (no influence of the sample on the temperature measurement) and that chemical compatibility issues (reaction between sample and temperature sensor) do not play a role. Additional components, such as beam knifes, or special sample holders can usually be mounted in the attachments.

Basics of heat transfer

While a number of different parameters can be altered during NAXRD, the most common one is temperature.

Generally, there are three types of heat transfer: conduction, convection, and radiation.

Conduction is the transfer of heat by thermal motion of the atoms within a material. The ability of a certain material to transfer heat is quantified by its thermal conductivity. As mentioned before, the thermal conductivity of the sample is especially important for direct heaters as it greatly influences the temperature deviation in these instruments.

Convection is the transport of heat by fluids (gases and liquids). Therefore, this type of heat transfer is highly influenced by the pressure and the type of gas present. In general, low-molecular weight gases have a much higher thermal conductivity compared to heavy weighted gases.

Radiation is the transfer of heat by electromagnetic waves. This type of heat transfer is independent of a medium, but the amount of transferred heat is highly dependent on the temperature (T to the power of 4 dependence).

Comparison of heater types

In principle, there are two types of heaters: direct heaters and environmental heaters. Direct heaters are NAXRD attachments that either have a sample holder that is placed on a resistance heater (Figure 3, A) or are so-called strip heaters, where the sample is directly placed on a resistively heated heating strip (Figure 3, B). The advantage of the former is that a cryostat, which also allows cooling of the sample, can be introduced. In contrast to that, very high temperatures (up to 2,300 °C) and fast heating rates can be achieved with strip heaters.

The second important type of heater is the so-called environmental heater (Figure 3, C). In contrast to direct heaters, environmental heaters heat the sample from all sides. This ensures a very homogeneous temperature distribution around the sample. Moreover, due to the design of the instrument it is possible to spin the samples by using sample spinners. This helps to improve the counting statistics and minimizes the influence of preferred orientation of the powder which would otherwise result in deviations from the expected relative peak intensities.

The heater type not only influences the temperature distribution around the sample, but also has a critical influence on the temperature accuracy of the instrument, as the temperature is measured inside the sample holders.

For a direct heater the heat is transferred from the resistively heated surface from below. This results in a temperature deviation between the measured temperature of the sample holder and the temperature on the surface of the sample. The deviation is highly dependent on the thermal properties of the sample. Critical parameters that influence this temperature deviation are, e.g., the heat conductivity, emission properties, and the thickness of the sample.

In contrast to that, due to the homogeneous temperature distribution inside the instrument provided by an environmental heater, the temperature deviation between the temperature sensor and the sample surface is minimized.

Temperature Validation

In general, the use of NA-XRD attachments requires calibration of the temperature read-out due to unavoidable differences between displayed temperature and real temperature on the surface of the sample. (As mentioned before, the temperature is usually measured in or close to the sample holder and not directly on the surface of the sample.) The term “calibration” can only be applied if certified standard materials are available. However, no such materials exist for NA-XRD. There are standard materials for various other thermal analysis methods like dynamic scanning calorimetry (DSC), but as the experimental conditions differ quite significantly, those can´t be applied for NA-XRD. Commonly accepted reference materials with “well-known” thermal properties are used instead. Therefore, the term “temperature validation” instead of “temperature calibration” is used.

There are different methods for temperature validation, and the influence of sample properties, heater types, and experimental conditions have to be considered for proper validation. Additional information on this can be found in the “Temperature validation for non-ambient XRD” wiki article.

Thermal Height Expansion

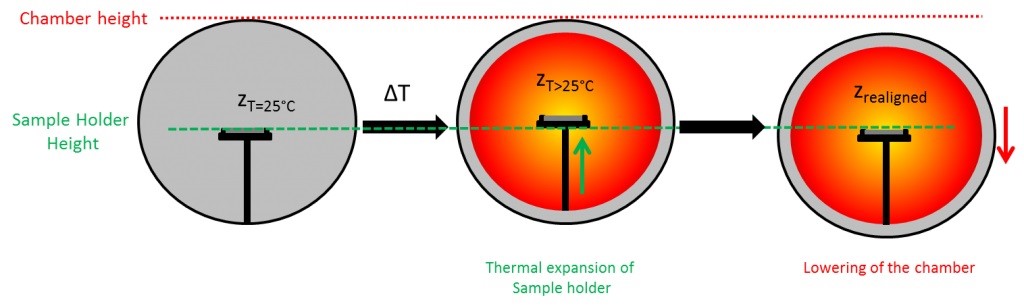

Almost all materials expand upon heating. This effect has to be accounted for in NA-XRD attachments as otherwise the sample would not stay at the centre of the goniometer, which would result in peak shifts. The way this correction is performed is schematically shown in Figure 4.

After installation of the XRD attachment, the height of the sample holder is aligned (left picture) at room temperature (ZT=25°C). Upon heating, the sample holder will expand, which means that the sample is above the initial value for the correct height (middle picture). To keep the sample at the pre-aligned position at elevated temperatures, the height of the instrument is reduced (right picture). This can be done either manually on the adapter of the instrument or in a more comfortable way automatically with a so-called Z-stage (see chapter 4.1 for further information). In general, it is highly recommended to use a Z-stage for non-ambient experiments, as this allows the performing of fully automated temperature batches without the need for any user interaction throughout the experiment.

The thermal expansion is heavily dependent on the type of instrument (direct heater or environmental heater), the atmosphere inside the instrument, and the pressure. For accurate experiments it is recommended to calibrate the thermal expansion of the sample holder under exactly the same conditions that will also be used for the sample measurement.

Calibration of thermal height expansion

The height of the sample holder (and therefore also the sample) is a function of the actual temperature.

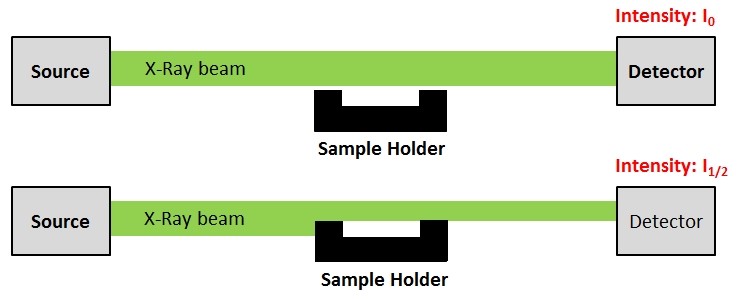

In practice, this function can be determined by measuring the thermal expansion of the sample holder at different temperatures. The most comfortable way to measure the thermal expansion of the sample holder is by using the primary beam of the diffractometer. By measuring the intensity of the uninterrupted primary beam I0 and then slowly moving the sample holder into the beam, until only half of the primary beam intensity remains (I1/2), the height of the sample holder can be aligned precisely. Figure 5 gives a schematic overview of the method.

Depending on the diffractometer used and the non-ambient equipment, the temperature-dependent expansion values can be stored in the program which adjusts the height of the instrument. It is sufficient to use temperature steps of 100 °C. All values in-between are interpolated. For all following experiments the actual temperature value of the heater is read-out and the height of the instrument is adjusted automatically.

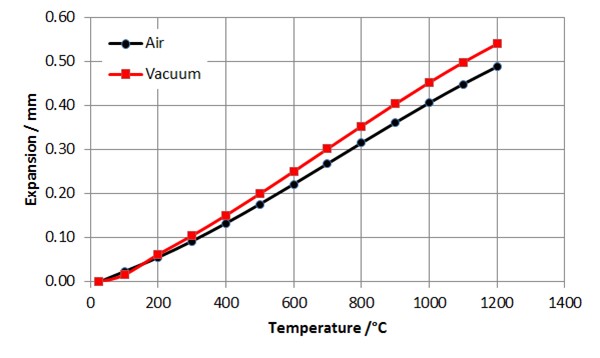

Figure 6 shows an example for the thermal expansion of the sample holder of an environmental heater, measured in air and vacuum.

In this case, data were measured up to 1200 °C. The expansion of the sample holder at 1200 °C is nearly 490 µm in air, whereas it is 540 µm in vacuum.

Applications

Due to the variety of NA-XRD attachments, the application fields are also widespread and range from simple observation of phase transitions to highly complex studies of, e.g. catalytic reactions. One has to keep in mind that all materials have different chemical, physical or mechanical properties under non-ambient conditions compared to those at standard conditions. As a consequence, studying these differences is necessary to fully understand the material of interest.

Mineralogy

Mineralogical applications of NA-XRD comprise studies of phases (different minerals or solid-solutions in mineral groups) yielding phase diagrams, which show the stability of phases depending on, e.g. temperature, pressure, or composition. A lot of phase changes are also dependent on the presence of fluids (e.g. de/hydration of zeolites and clays).

NA-XRD is also an important technique for material research which uses minerals as raw materials, e.g. for sensor devices, ferroelectrics / piezoelectrics or permanent magnets.

Furthermore, cements and especially their hydration/dehydration reactions are frequently studied with NA-XRD. During hardening of cements, several mineral reactions occur. The type of reactions and the composition of the final cement product strongly depend on humidity and also temperature.

Metallurgy

NA-XRD in metallurgy is focused on development, formation, and processing of metals, steels, and alloys.

Hardening and strengthening of the alloys is often dependent on the heating and cooling rates. Non-ambient diffraction allows for the study of structural and textural as well as compositional changes during such heating and cooling processes. On the other hand, sintering of metal powders can be easily observed and optimized with NA-XRD.

Pharmacological industry

NA-XRD plays an important role in all production steps of the pharmaceutical industry: drug (API) development, storage and stability testing, quality control as well as crystallization studies. Understanding the stability conditions and properties of different phases is essential for the optimization of product processes and storage conditions. In some cases, amorphous phases are less stable and crystallize during contact with air and/or humidity, which makes in situ X-ray diffraction a powerful tool to evaluate the crystallization behavior of drugs.

Food industry

Numerous compositions and structures make food a complex system. Hence, qualitative and quantitative studies, among them non-ambient investigations, are necessary to determine storage, freezing, or heating behavior and stability. NA-XRD is a suitable technique, as in many processing steps, heating and cooling of food is required, and changing properties can be studied in situ.

Crystallization and melting behavior of oils and fats, for instance, have a strong influence on the properties of fat raw materials and of final products (e.g. desired texture properties of chocolate or ice-cream). Further examples are studies of shelf life (e.g. in refrigerators) or gelatinization of starch. Also, the behavior of cryoprotectants in frozen and dry food production requires profound investigation under non-ambient conditions.

Ceramics

Studying phase transitions at elevated or low temperatures is a necessity for developing new ceramic and ceramic-composite materials. The demand for new materials is related to the rapid progress in different application fields using ceramics as raw materials or final product (e.g., refractory industry, superconductors, automotive and aircraft industries, bioceramics).

As an example, phase transitions of ceramics can have a major influence on their mechanical strength (hardness or toughness). On the other hand, ceramics in refractory applications have to be highly temperature-resistant. Non-ambient diffraction is suitable for in situ investigations of the thermal properties of ceramic materials.

Chemical industry

Use of NA-XRD in the chemical industry is diverse and covers the investigation of nanomaterials, catalysts, batteries, piezoelectric, and magnetic properties of materials, hydrogen storage and fuel cells, air sensitive samples, calcination and sintering, and many more.

One very recent topic of interest in material science is research of storage behavior of gases like H2 and CO2. In situ studies of adsorption and desorption of such gases in suitable carrier materials are of key interest, e.g., for fuel cells. Even if gases like H2 cannot be directly measured with XRD, the change of the unit cell dimensions during the gas storage process provides insights into the usability of the material under investigation. Therefore, the ability to use different gases, pressures and temperatures provides a vast playground in this field of research.

Metal organic frameworks (MOF), e.g., play a major role in adsorption, gas separation, or catalysis. Fluid-induced changes of the MOFs can be investigated under controlled combination of atmosphere and temperature.

Thin films

A growing application field lies in development and production of thin films. Chemical and physical properties of the thin film materials strongly depend on temperatures (e.g. temperature-dependent strain and stress, thermal decomposition, annealing processes, microstructures as dislocations and defects), which makes non-ambient diffraction a suitable technique for their analysis.

Strain and stress in thin films have a major influence on hardness, toughness, or adhesion to the substrate. Furthermore, thermal straining is responsible for mechanical faults in micro- and optoelectric devices. Understanding the origin of strain and stress is therefore necessary for development of new thin film materials and appropriate production processes. On the other hand, different annealing temperatures may influence mechanical and optical properties as well as the thickness of the films.

Conclusion

NA-XRD provides a unique capability to analyze how materials respond to external stimuli, such as temperature, pressure, or environmental changes. This technique plays a crucial role in various scientific and industrial fields, offering insights into material behavior during phase transitions, crystallization, and other structural transformations.

Whether it's developing more durable alloys, optimizing drug formulations, or studying catalytic reactions in chemical processes, NA-XRD has proven to be an essential tool for understanding the complex interactions of materials in dynamic environments. Its ability to simulate real-world conditions and provide real-time data makes it a versatile and indispensable technique for advancing material science and technology.

The Non-ambient Guide

This free guide gives you a general introduction to non-ambient X-ray diffraction (NA-XRD). The content spans from instrumentation, analysis, and data interpretation to applications. The document is not explicitly dedicated to one specific non-ambient XRD instrument or one particular application area, but aims to give a global overview of the main instrumentation and applications.

References

- Touloukian, Y.S., (1977). Thermophysical Properties of Matter, Vol 13, Thermal Expansion of Nonmetallic Solids