A Comparison of XRF and XRD

What is XRF?

X-ray fluorescence (XRF) spectroscopy is an elemental analysis technique that determines the chemical composition of a material. In XRF, a material is bombarded with high-energy X-rays, causing its atoms to become excited and emit secondary (fluorescent) X-rays. The energy of these emitted X-rays is characteristic of the chemical elements present in the material, allowing for their identification and quantification.

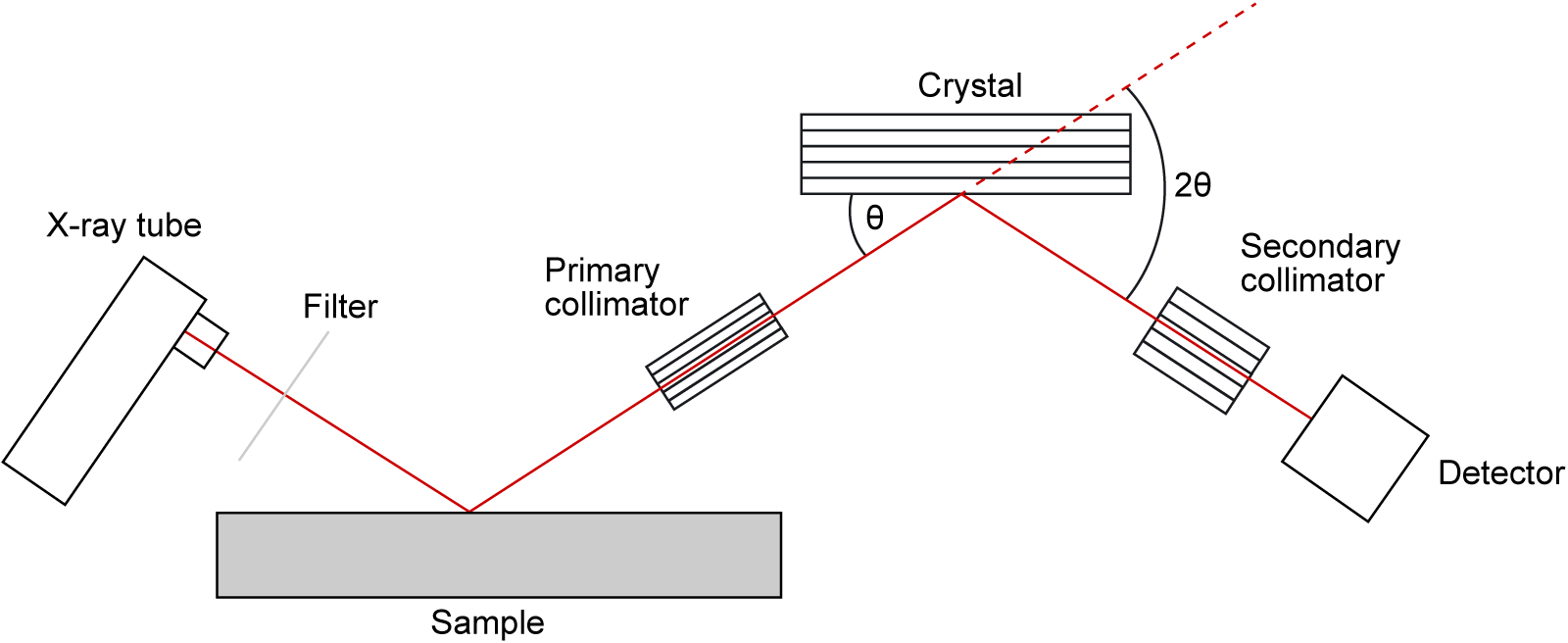

XRF can be sub-divided into two major branches, namely wavelength dispersive (WDXRF) and energy dispersive X-ray fluorescence (EDXRF). Both share the same basic principles of operation in terms of excitation of the sample, absorption within the sample, and correction for matrix effects, but differ in the way that the X-ray spectrum is dispersed. WDXRF uses an analyzing crystal (could be flat or curved) together with Soller slits to disperse the X-ray spectrum according to Bragg’s Law, whereas EDXRF uses a combination of cylindrical collimators, a high energy resolution solid-state detector, and an electronic multichannel analyzer to measure and disperse the X-ray spectrum. The result of these fundamental differences between the two techniques means that WDXRF measures a single wavelength at a time, while EDXRF measures the entire spectrum simultaneously.

What is XRD?

X-ray diffraction (XRD) is a technique used to analyze the crystallographic structure of materials. When X-rays are directed at a crystalline material, they are diffracted by lattice planes, originating from the periodic arrangement of atoms within the crystal lattice, according to Bragg’s Law. These lattice planes produce distinct peaks or reflections that are characterized by their position (2θ angle), intensity, and shape, to ultimately produce a diffraction pattern or diffractogram. The diffraction pattern produced can be analyzed to determine the material’s crystal structure, phase composition, and crystallinity.

Key differences between XRF and XRD

While both XRF and XRD utilize X-rays, their principles, outputs, and applications differ significantly. Below is a side-by-side comparison of the key differences between XRF and XRD:

| Aspect | XRF (X-ray Fluorescence) | XRD (X-ray Diffraction) |

| Purpose | Elemental composition analysis | Crystallographic structure analysis |

| Principle | Detects secondary X-rays emitted by atoms in the material | Measures diffraction of X-rays by crystal lattices |

| Type of Information | Qualitative and quantitative elemental composition (through matrix-specific calibrations) | Qualitative and quantitative (crystalline) phase composition, crystal structure, lattice parameters, amorphous content. |

| Sample requirement | Works for both crystalline and amorphous materials | Primarily for crystalline materials |

| Output | Spectrum showing peaks for each element’s characteristic X-rays | Diffraction pattern (diffractogram) of intensity vs. 2θ angle |

| Example result | Sample has X mg/g Fe, Y mg/g…. |

Sample consists of: 30 % Fe2O3 20 % xy 50 % armorphous content |

| Common use cases | Mining, environmental analysis, metal alloys, forensics | Materials science, geology, chemistry, pharmaceuticals |

| Speed | Fast and suitable for bulk analysis | Can take longer, might require more precise alignment and conditions |

Similarities between XRF and XRD

Apart from the differences, the two techniques share some similarities between each other as listed below:

- Non-destructive: Both XRF and XRD are non-destructive techniques, meaning the sample remains intact during analysis.

- Use of X-rays: Both methods rely on the interaction of X-rays with the sample to gather information.

- Versatile: Both techniques are widely used in various industries, including materials science, geology, and environmental monitoring.

- Qualitative and quantitative analysis: Both techniques provide qualitative and quantitative information during analysis.

Advantages of XRF

- Rapid elemental analysis: XRF provides fast results for determining the presence and concentration of elements, making it ideal for large-scale and high-throughput applications.

- High accuracy: Provided that the calibration methods used for analysis are fit for purpose, XRF will give precise quantitative data on elemental composition.

- Amorphous and crystalline materials: XRF can analyze both amorphous and crystalline materials, making it more flexible for materials that do not have a well-defined crystal structure.

- Portable solutions: Portable XRF analyzers allow for in-field testing, making it useful in mining, construction, and environmental applications where on-site analysis is needed.

- Minimal sample preparation: For hand-held XRFs, little to no sample preparation is needed, making it ideal for analyzing priceless artifacts or scrap material for recycling.

- Wide range of CRMs: Certified reference materials (CRM) are widely used and available in a range of industries and matrices. This ensures that laboratories are able to find reference materials that closely match their samples.

Advantages of XRD

- Crystal structure information: XRD provides detailed information about the arrangement of atoms in crystalline materials, allowing researchers to determine the material's phase and structure.

- Phase identification: XRD can identify different crystalline phases in a sample, which is critical for studying materials that may contain multiple phases (e.g. quartz, muscovite), such as alloys, minerals, or ceramics.

- Polymorphism: XRD is able to distinguish between different polymorphs of a material with the same chemical composition.

- Lattice parameter determination: XRD allows the measurement of unit cell dimensions and can detect subtle changes in the crystal structure, such as lattice strain or defects.

- Crystallinity and texture analysis: XRD is widely used to evaluate the degree of crystallinity and the preferred orientation (texture) of materials, which are important properties in material science and engineering.

- In-depth structural analysis: XRD can be used for more sophisticated structural analysis, including Rietveld refinement, which provides information about lattice parameters, the atomic positions in a crystal, crystallite size, and texture.

- Diffraction data databases: Free and paid versions of diffraction data compiled into databases that cover a wide range of application fields are available.

Applications of XRF vs. XRD

XRF applications

XRF is commonly used in industries such as mining, environmental monitoring, metallurgy, and quality control for rapid elemental analysis.

- Mining and exploration: XRF is used to determine full chemical analysis of ores and minerals for metal content, helping geologists assess the economic potential of deposits.

- Environmental analysis: XRF is used to identify and quantify contaminants in soils, sediments, and water, including heavy metals like lead, arsenic, and mercury.

- Metallurgy: XRF is extensively used in metal production to ensure alloy composition and quality.

- Art and archaeology: XRF is employed for non-invasive analysis of historical artifacts, paintings, and ceramics to determine their elemental composition.

XRD applications

XRD is extensively used in materials science, geology, chemistry, environmental and health monitoring, food production, and pharmaceuticals to identify crystalline phases, characterize unit cell dimensions, and detect changes in crystal structure.

- Materials science: XRD is used to characterize new materials, assess their phase purity, and understand the relationship between their properties and crystal structures.

- Pharmaceuticals: XRD is important for identifying and controlling different polymorphic forms of drugs, as different forms can affect a drug’s efficacy and stability. Non-ambient XRD investigate the stability of an Active Pharmaceutical Ingredient (API) under high/low temperatures or high humidity.

- Geology: XRD is used to identify minerals and analyze rock formations, helping geologists understand the conditions under which rocks formed.

- Food: XRD is used to study the crystalline and amorphous content, as both can influence the mouth-feel.

- Environmental: XRD is capable of determining asbestos and respirable silica in health and environmental monitoring.

- Polymers: XRD helps determine crystallinity in polymers and phase transitions.

- Ceramics: XRD is used to determine additive stability in ceramics during processing.

- Non-ambient XRD: Performing non-ambient XRD on materials can provide valuable information on the structural behavior, stability, and reaction mechanisms of the materials under different environmental conditions.

Choosing between XRF and XRD

The choice between XRF and XRD depends on the type of information required for the analysis:

- If you need elemental composition, including trace elements in both crystalline and amorphous materials, XRF is the ideal method.

- If you are studying crystal structure, phase identification, or lattice parameters, XRD is the preferred choice.

In many cases, both techniques are complementary. For example, XRF can be used to determine the elemental composition of a material, while XRD can provide insights into how those elements are arranged in the crystal lattice. Using both techniques together can give a comprehensive understanding of the material’s properties.

Conclusion

XRF and XRD are both powerful techniques that offer unique insights into materials. XRF excels in providing quick and accurate elemental analysis, while XRD is essential for understanding the crystalline structure and phase composition of materials. Each technique has its strengths, and they are often used together for comprehensive material characterization in research and industry.

References

- Jenkins, R., & Snyder, R. L. (1996). Introduction to X-ray Powder Diffractometry. Wiley-Interscience.

- Beckhoff, B., Kanngießer, B., Langhoff, N., Wedell, R., & Wolff, H. (2006). Handbook of Practical X-Ray Fluorescence Analysis. Springer.

- Pecharsky, V. K., & Zavalij, P. Y. (2009). Fundamentals of Powder Diffraction and Structural Characterization of Materials. Springer.

- Willis, J., Feather, C., Turner, K., (2014). Guidelines for XRF analysis, Shumani Mills Communications