Particle Size in Building Materials: From Cement to Bitumen

Building materials are materials used for construction. These include naturally occurring substances, such as sand and clay, as well as man-made products. Particle size influences different aspects of building materials and requires proper quality control.

For raw materials, particle size and shape strongly affect processing and workability as well as powder flowability and reactivity. This is because the particle surface area increases with decreasing particle size. Viscosity changes and sedimentation processes are connected to size and shape alterations as well.

The final product’s look and feel are changed by altering the particle size and shape. Surface properties and reactivity might be affected, or particle-size-dependent roughness and inhomogeneity could influence the physical properties. In the manufacturing process, large particles might lead to nozzles, mills, or filters being blocked. Significant amounts of fine dust might also be generated.

Sophisticated particle size and shape determinations can be used to control grinding processes and to identify critical steps in the manufacturing process. For this application, a robust laser diffraction or dynamic image-analyzing instrument that covers the µm to mm range would be the instrument of choice.

Laser diffraction generates a volume-based particle size distribution, which cannot detect small amounts of outlying particles. Despite this limitation, laser diffraction is a fast analytical technique that conforms to numerous ISO standards, making it a preferred method for quality control applications. For the detection of irregular particles or outliers, dynamic image analysis is recommended. This technique provides a number-based distribution that emphasizes both oversized and undersized particles. While primarily employed in research and development, dynamic image analysis is also applicable in quality control settings.

Particle size for cement and concrete

Cement is a mixture of a variety of materials, including limestone, shells, and chalk or marl, combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore. In cement production, the grinding stage is a very energy-consuming step. Narrowing down the particle size distribution saves energy and reduces costs. The average particle size of cement is usually between 10 µm and 20 µm.

In addition to the economic aspects of cement production, particle size has a major influence on the properties of the final product. Together with its chemical composition and specific surface area, the particle size distribution is a major factor that affects the hydration curve of cement as well as the strength of the hardened paste. Specifically, reducing the average particle size leads to decreased setting time and enhanced early strength. In contrast, the importance of coarser particles grows with the aging of the cement. The width of the particle size distribution also determines the packing density and water demand of cement and other building materials.

Because different raw components have different grinding susceptibilities, size diminution during grinding is not straightforward. The duration of a grinding period needs to be optimized and controlled by monitoring the particle size distribution at almost every step of the process.

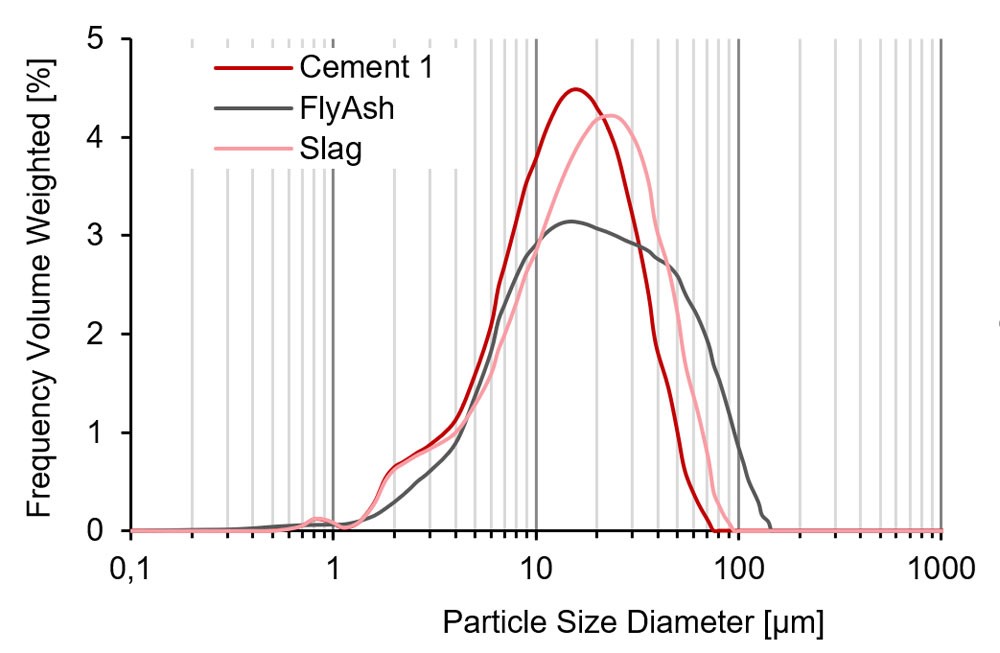

In this cement particle size distribution, the different sizes of cement particles are separated into size classes, and the relative amount can be compared. The graph shows the mean particle size distribution of a cement sample (Cement 1) compared to two cement replacers (FlyAsh and Slag). All samples have an almost monomodal distribution with a maximum between

15 µm and 25 µm. This shows the similarity between cement and cement replacers regarding particle size.

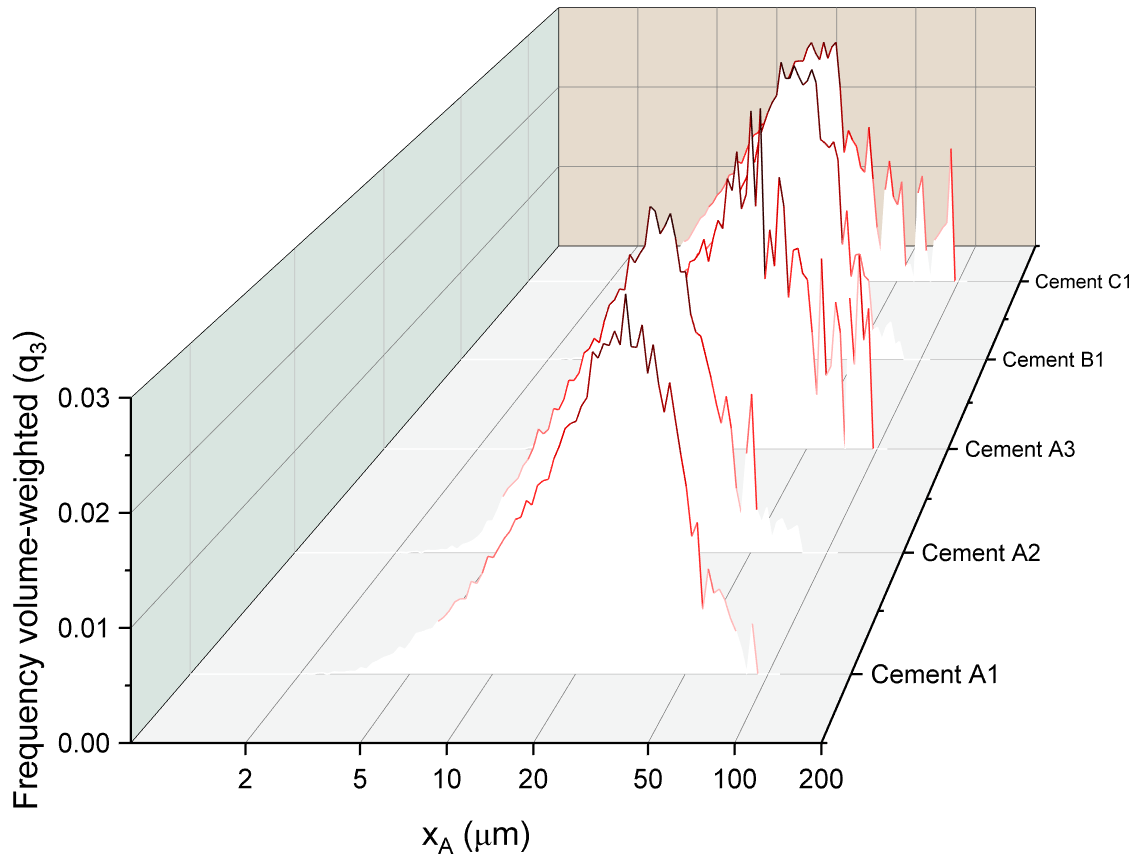

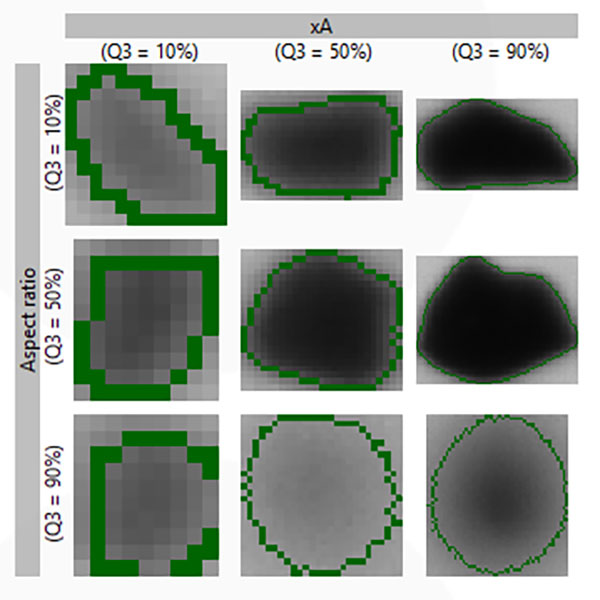

In addition to particle size, particle shape is a crucial parameter to monitor. The flowability and water demands related to cement can vary significantly between regular (spherical) and irregular particles. Both the fineness and shape of cement particles are key factors in quality control, as they directly influence water demand, flowability, and overall cement performance. Five cement samples were analyzed using dynamic image analysis, returning both size and shape distributions. All samples exhibited a broad monomodal size distribution, primarily ranging from 5 μm to 60 μm. Particle shape was evaluated based on aspect ratio and compactness, with one of the quick-setting cement samples displaying the most regular (spherical) particles.

Gypsum

Gypsum is a widely used building material used as a finish for walls and ceilings. It is also sold as gypsum board or plasterboard and as gypsum blocks for building construction. It can be used for mortar, plaster, or as a binder. An optimum particle size distribution is a prerequisite for a desired setting time, compressive strength, or density. By increasing the fine fraction, e.g., the setting time will decrease but the water/gypsum ratio will increase.

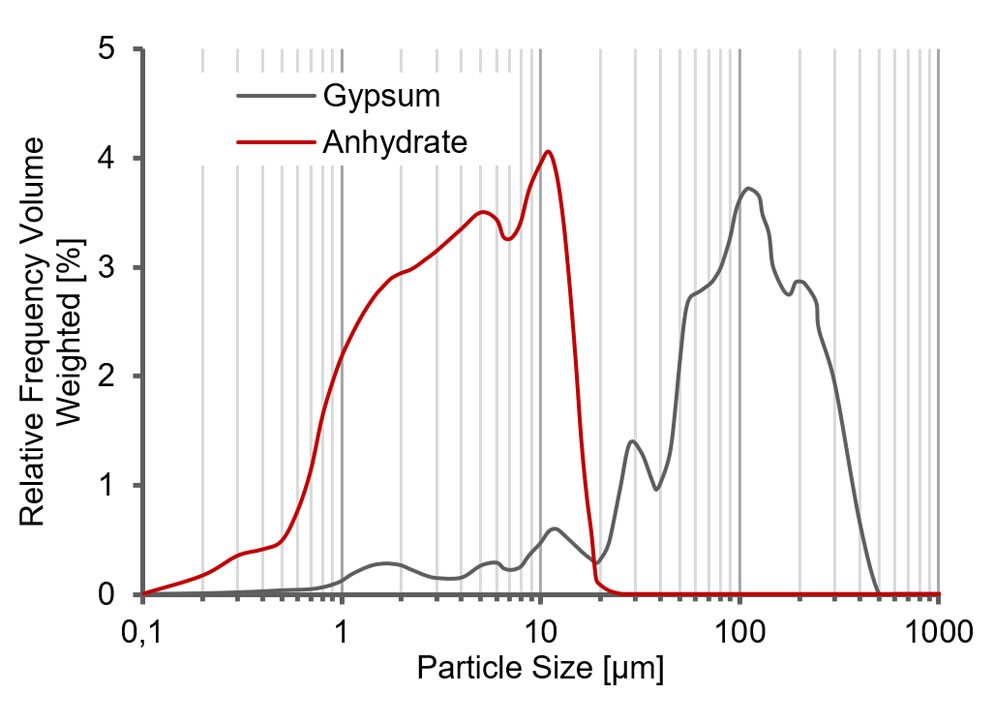

The graph compares the particle size distributions of gypsum powder and anhydrite powder measured in the dry mode of Litesizer DIF. Both distributions are multimodal and cover completely different size ranges. While the main fraction of anhydrite is between 1 µm and 10 µm, that of gypsum is between 40 µm and 300 µm.

Bitumen emulsions

At ambient temperature, bitumen is not processable. Therefore, different technical methods are used for processing. One technique is heating bitumen until it reaches the liquid state. Another possibility is processing bitumen into an emulsion. Bitumen emulsions are colloidal mixtures of bitumen and water stabilized by emulsifiers and other additives. In this ready-to-use state, bitumen can be stored, transported, and further processed.

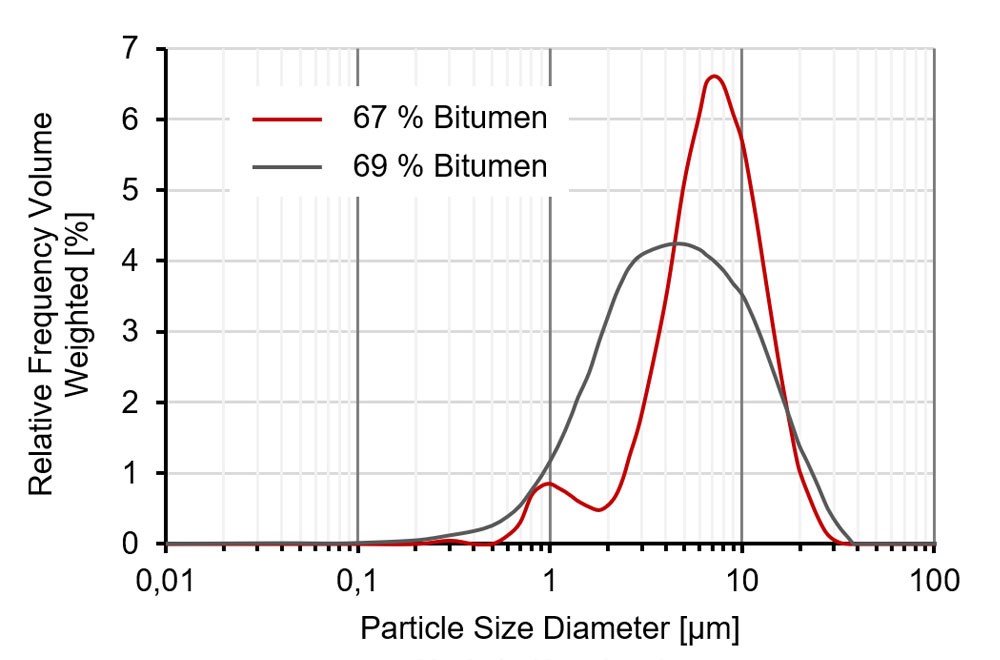

In order to ensure proper emulsification, the droplet size of the bitumen and the choice of emulsifier are important. Both affect the processability and the storage stability. Emulsifier molecules attach to the surfaces of the bitumen particles, giving the particles a uniform electrical charge. Depending on the charge (positive or negative), a distinction between cationic or anionic bitumen emulsions can be made, which defines the interaction with stone materials such as quartz, granite, or basalt. The technical application of bitumen emulsions is determined by the bitumen’s charge, the mass fraction of bitumen, emulsifier, water, and the bitumen droplets’ size. The graph shows typical particle size distributions for bitumen emulsions.

Silicone paste/rubber

A completely different building material is a silicone paste or rubber, which is predominantly used for sealing gaps, joints, and crevices. It also prevents lime from sticking to metal, and it can be put onto curtain walls or silicone membranes.

Silicone rubber’s mechanical behavior, such as the ultimate strength, elasticity, fracture toughness, and fracture tensile strain, is strongly influenced by the particle size of the additives and the polymers themselves.

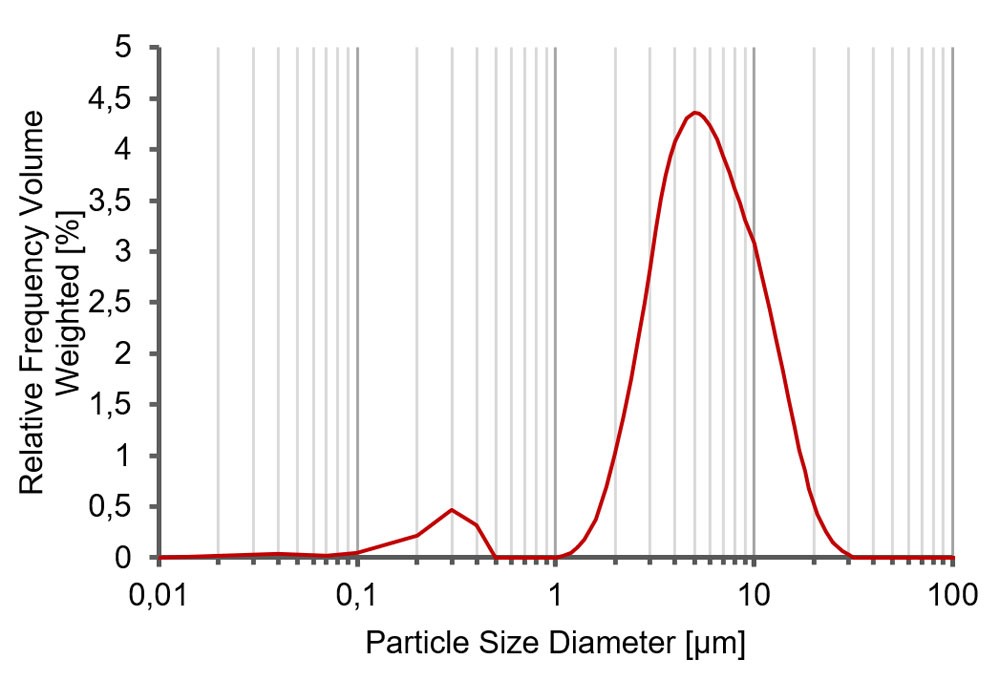

The graph shows a silicone paste particle size distribution dispersed by sonication in isopropanol.